TEXTILES TRANSFORMING INTO FURNITURE

This project was made in collaboration with RISD students Isabel Jane Marvel (MArch ’24) and Maya Weber (MA IntAr ’24).

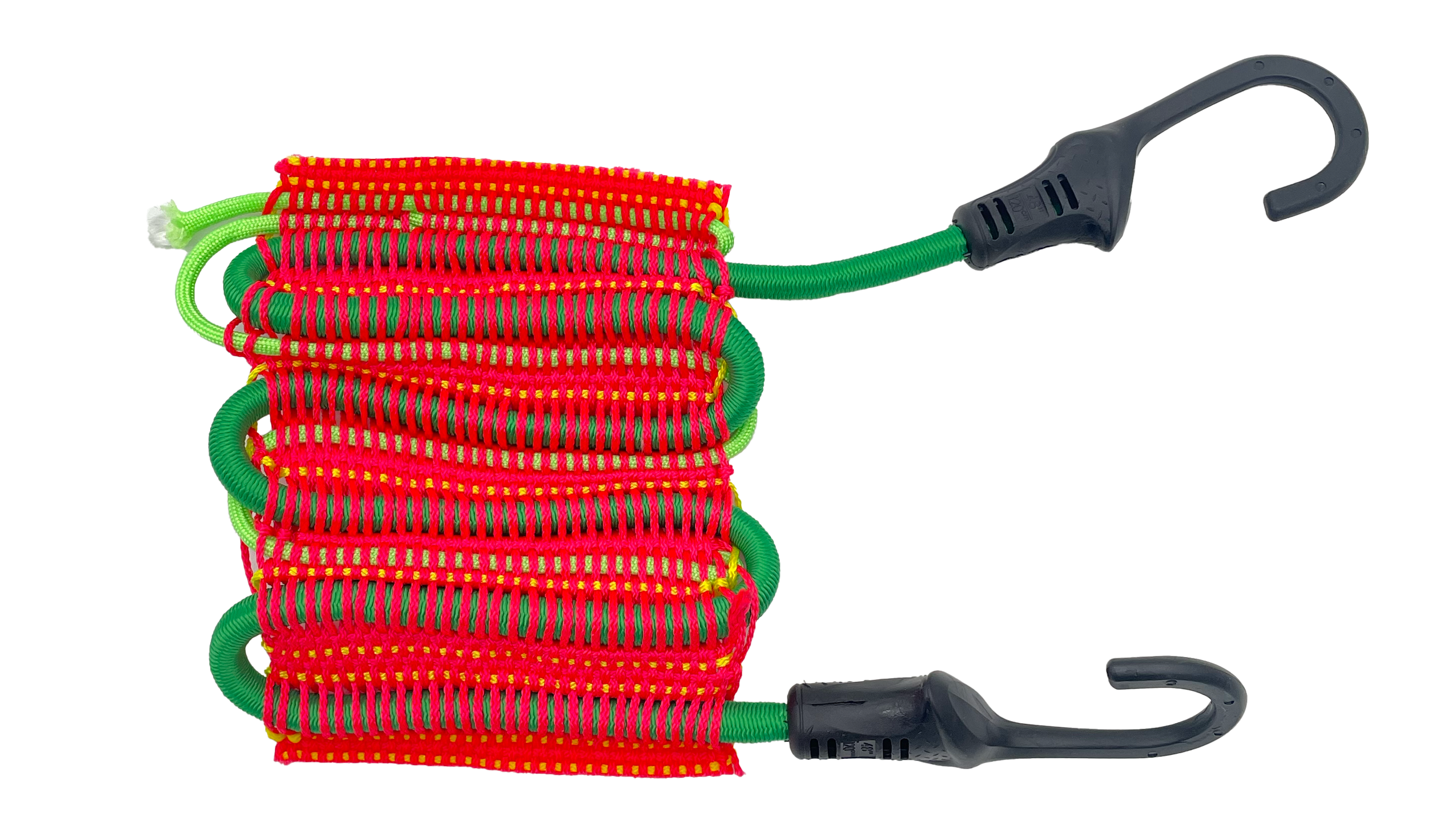

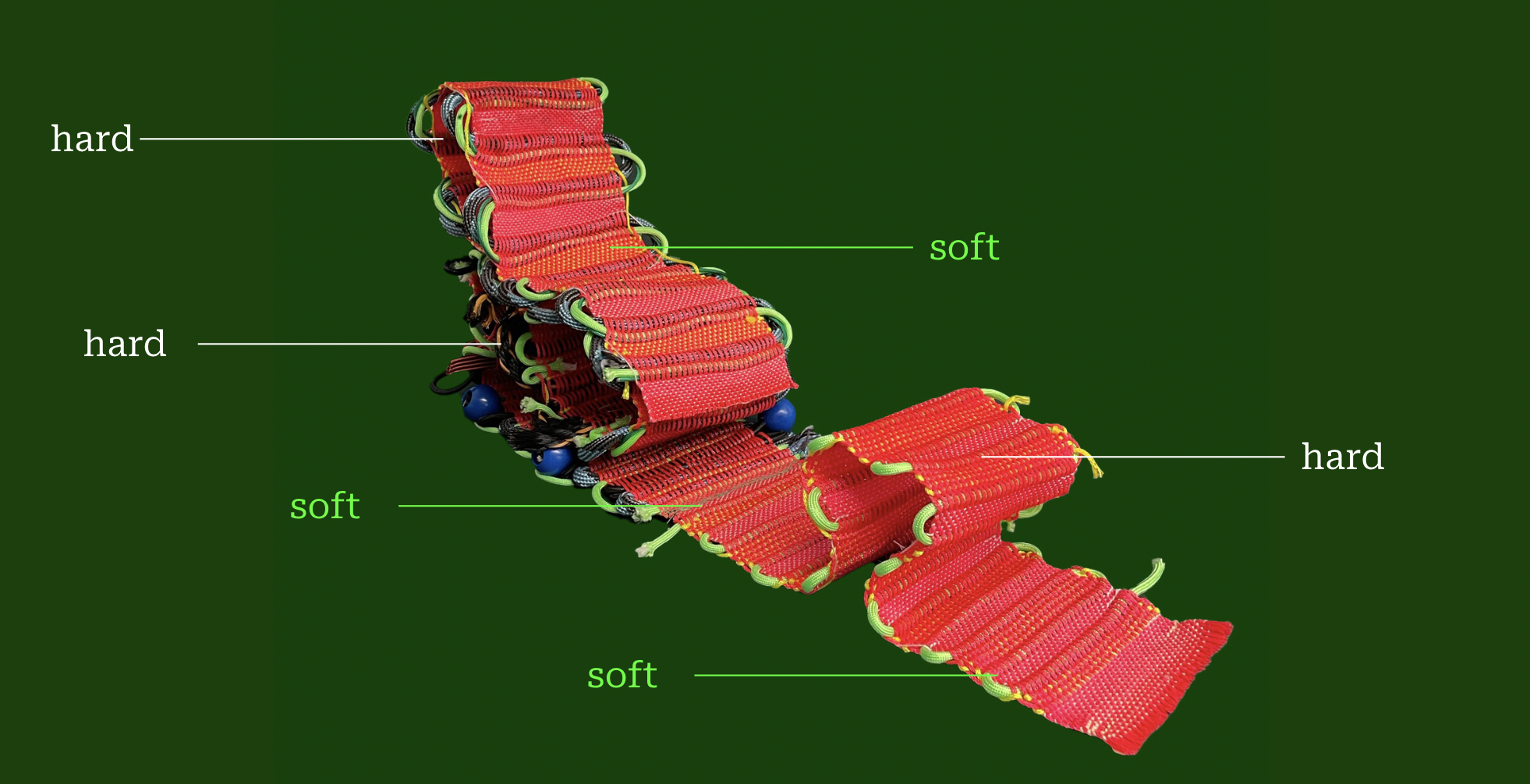

Here, textile folds and lifts from a flat rug into a three-dimensional form of a chair, a fluid piece alternating between soft for comfort and hard.

This structure focuses on sustainability, industrial, and off-the-shelf materials.

This structure focuses on sustainability, industrial, and off-the-shelf materials.

FIRST SAMPLING

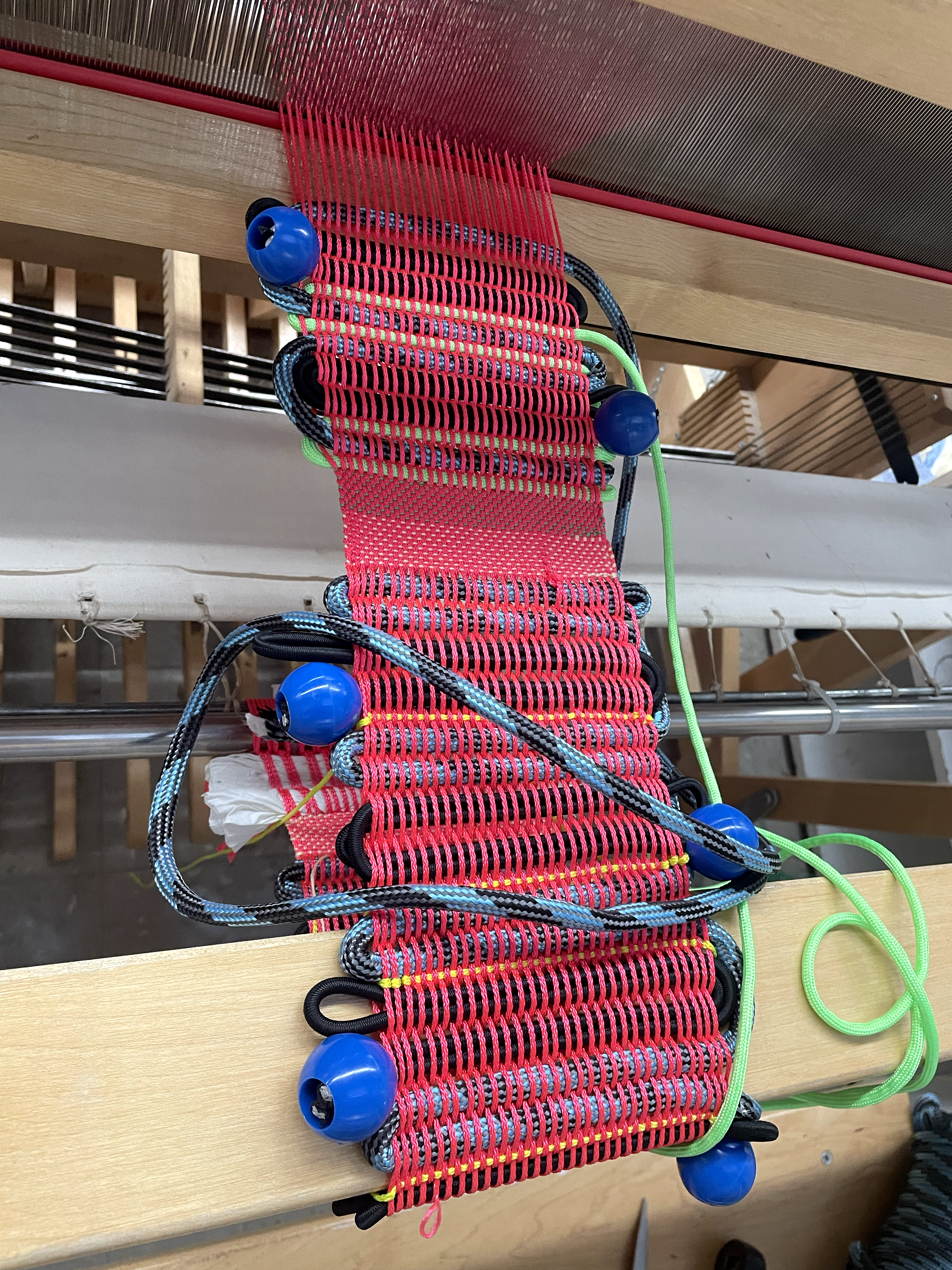

Textile samples on 8 harnesses loom made by Ella Son

MATERIAL SELECTION & RESEARCH

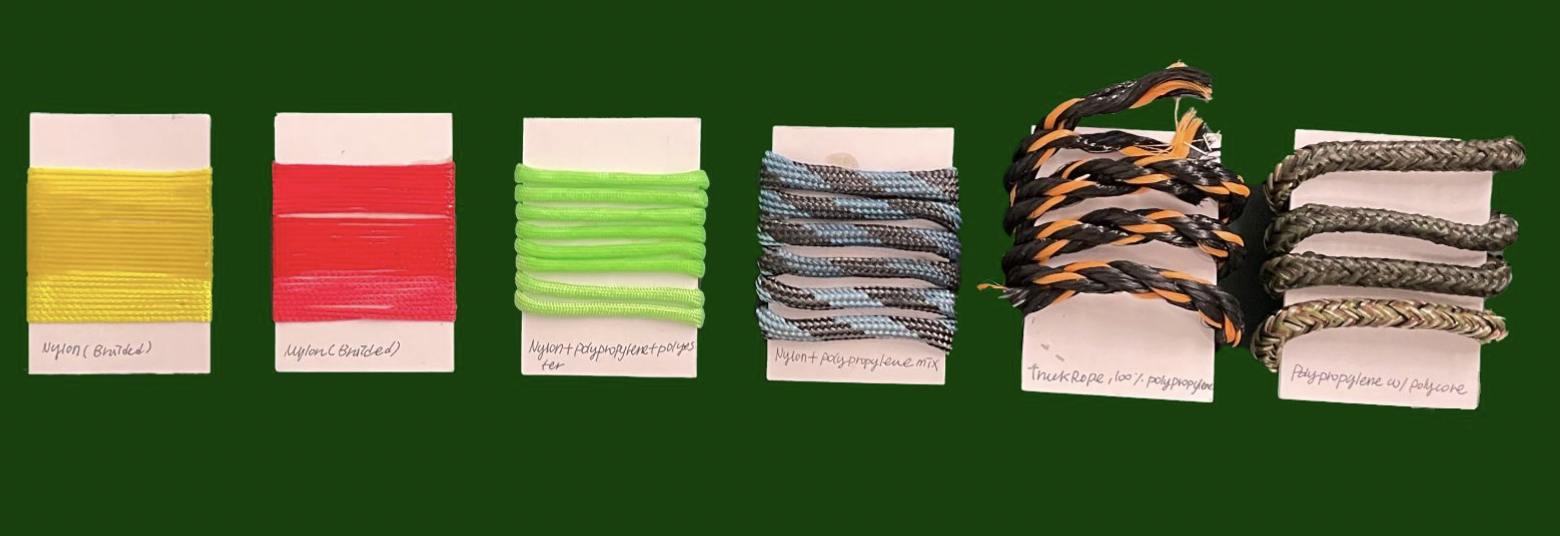

RESEIN TEST ON THE SAMPLE CARDS

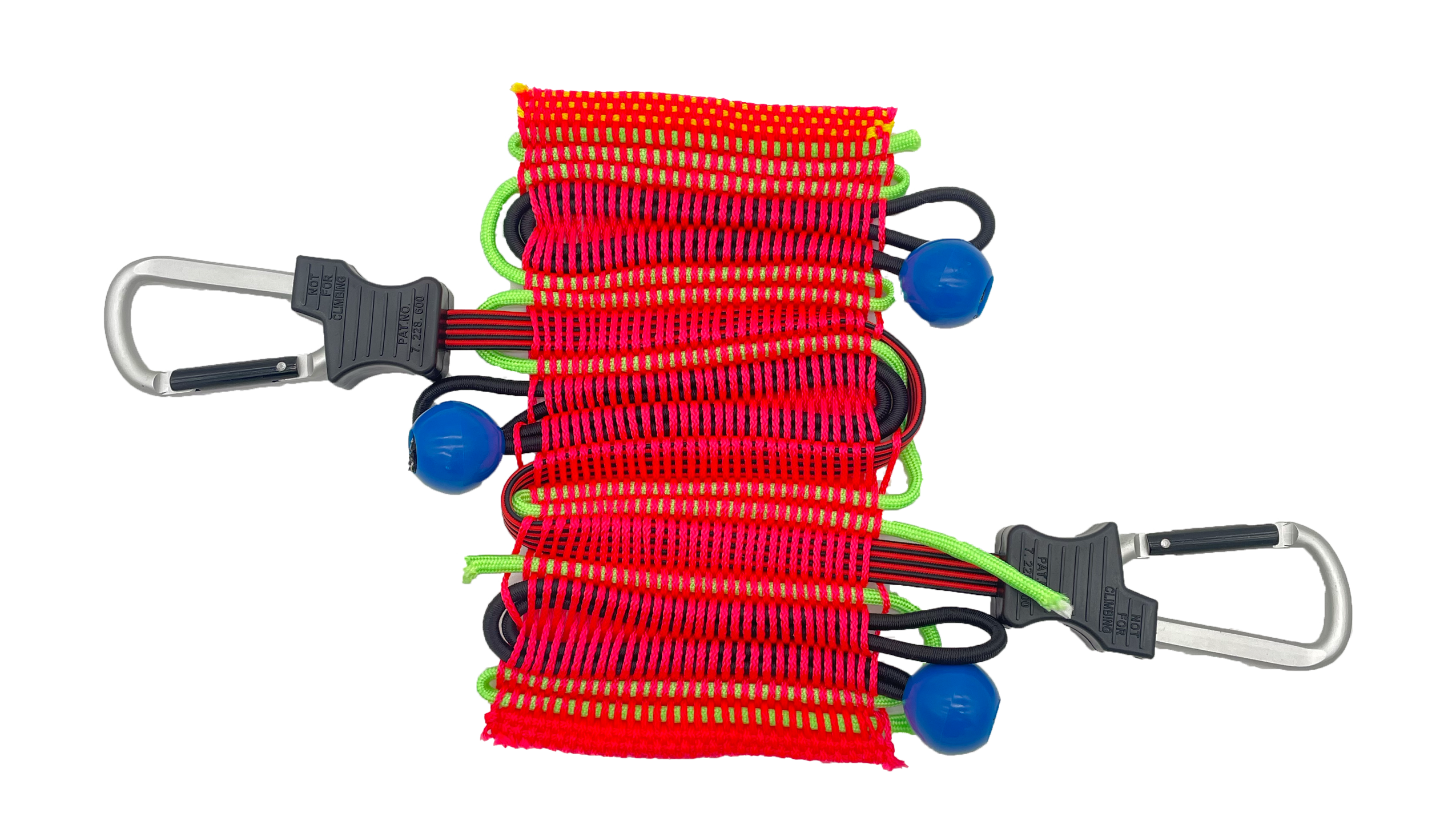

Before we move on to the real scale, we tested how resin changes the color on each cord’s surface.

From the left, Braided Yello Nylon, Braided Pink Nylon, Nylon+Polypropyrene+Polyester, Nylon+Polypropylene Mix, Trunk Rope+100% Polypropyrene, and Polypropyrene+Polycore.

SEWING AND CONSTRUCTING FOR QUARTER SCALE

Processed by Isabel Marvel & Maya Weber

CUSTOMIZATION FOR REAL SCALE

We created the custom loom frame with the wood and hook nails. Designing a custom frame loom allowed us to weave a specifically dimensioned textile, reducing unnecessary material usage. Using chunky and thick climbing ropes for the warp and weft set up adds a unique and visually appealing dimension to the weaving process.

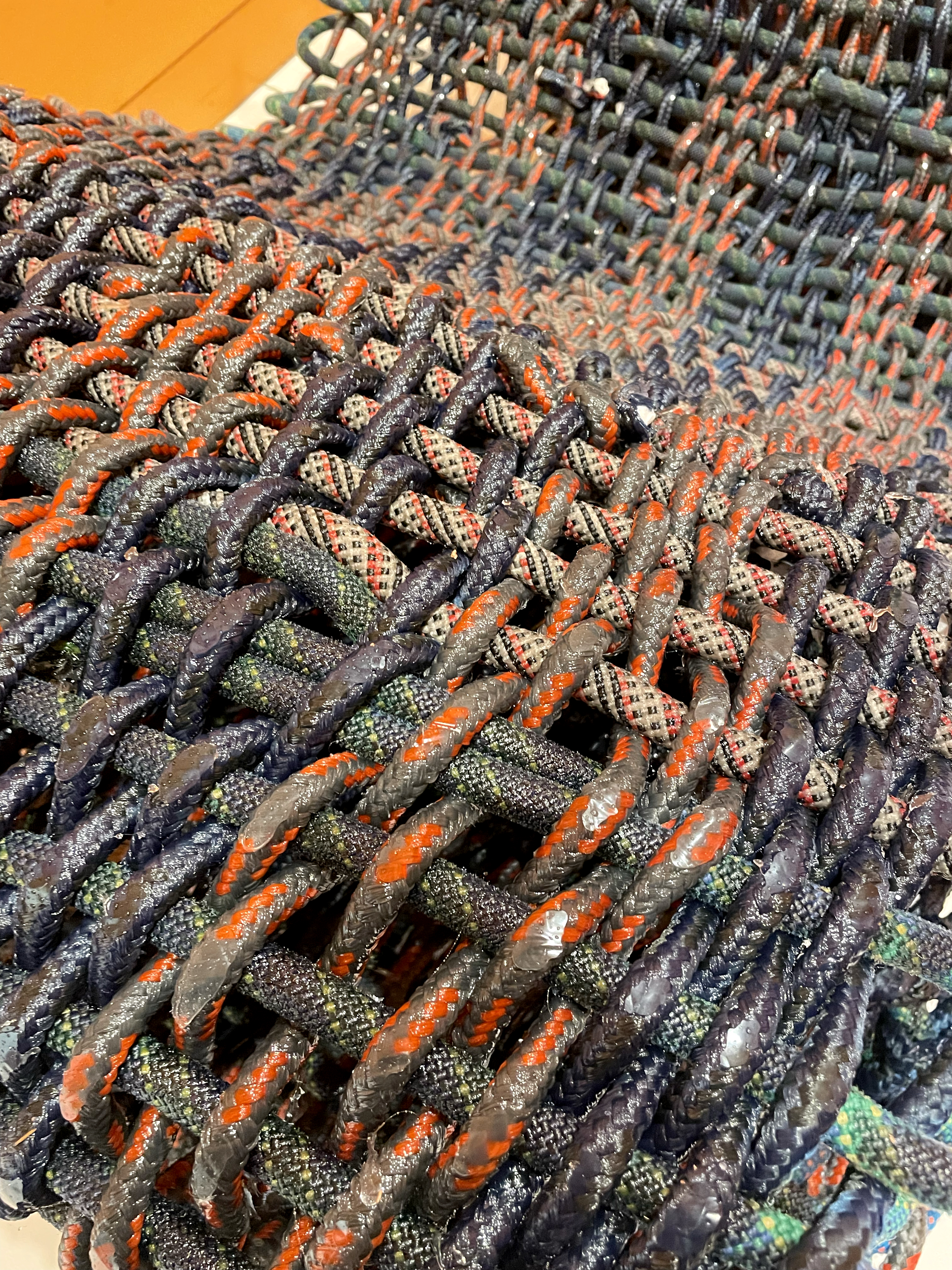

We collected climbing ropes from local climbing gyms in Providence and Boston and recycled climbing ropes for weaving not only reduces waste but also gives a new life to discarded items.

Hand-made loom by Isabel Jane Marvel x Maya Weber x Ella Son

We collected climbing ropes from local climbing gyms in Providence and Boston and recycled climbing ropes for weaving not only reduces waste but also gives a new life to discarded items.

Hand-made loom by Isabel Jane Marvel x Maya Weber x Ella Son

Idea sketch by Rhino drew by Isabel Jane Marvel

CONNECT JOINTS, EDGES, AND TRIMMING

STRUCTURE FOR THE RESIN

MDF Wood Cut by CNC

RESIN APPLICATION

FINAL PRESENTATION